On June 2019, CAD Developer Dassault Systèmes announced that the beta version of SolidWorks 2020 is now available. It is still in developmental stages, but it promises improved performances for drawings, assemblies and simulations, as well as more streamlined workflows.

Dassault Systèmes gave a preview of what to expect with this newest release at last February’s SolidWorks World. Here are a few of its exciting features as covered by Angelle Erickson, CAD and 3D Printing Technology Writer at Fisher Unitech:

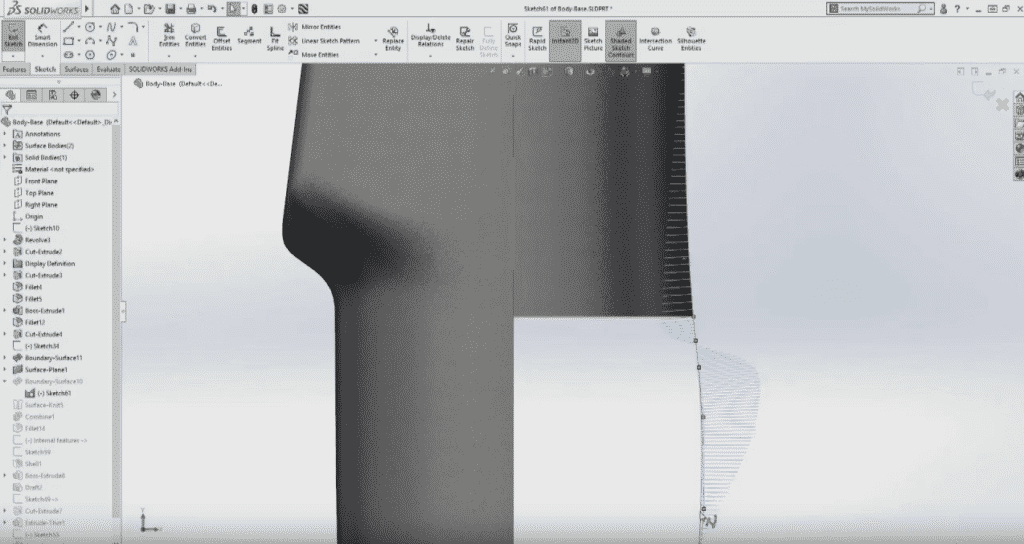

Torsion Continuity Sketch Relation

The first new features announced surround the redesign of a hand-held anemometer to improve its grip, but in order to do that, you would have to redesign the lower half of the handle to give it more shape. Curvature combs have been available for a while that inspects how smooth a surface will be, but in SOLIDWORKS 2020 users can make a surface even smoother by adding the new torsion continuity relation to achieve G3 curvature between curves. Users can adjust the spline as well as vertices to create surfaces that meet their liking. Zebra stripes can also be enabled to help see any wrinkles or defects in the surface.

(Image Credit: SolidWorks)

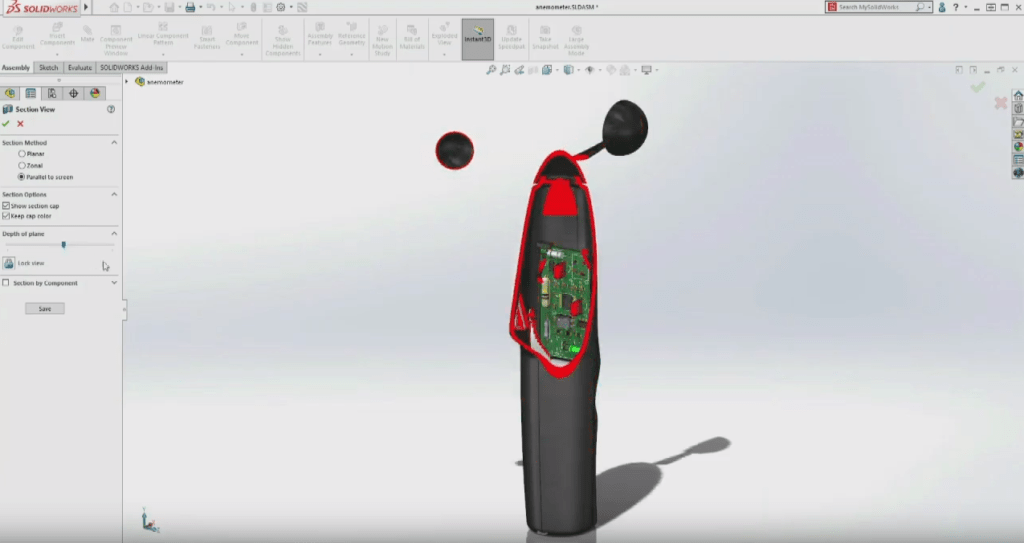

Sure, you can use the traditional planar section views to look inside your model to see if you have the right clearances, but why not use the new parallel to screen section method? This creates the section plane parallel to the screen and allows you to control the depth of the section. As you rotate your model, it’s sectioned dynamically and you can choose which components to section. Outside of this section command, this dynamic sectioning stays active as the model is rotated but zooms are unaffected. The depth of the section plane can be controlled using the scroll wheel with the control key pressed. This new sectioning method allows you to really look into your design to check clearances.

(Image Credit: SolidWorks)

New Assembly Functionality

Working on large designs with multiple designers can be a challenge especially when design work needs to reference multiple subassemblies. With the new envelope publisher in SOLIDWORKS 2020, users can simply select the components needed and a destination assembly. The selected components are then created as envelopes for easy reference and mating. Being able to work on a certain part but correctly mate the connectors without needing to duplicate parts or open the top-level assembly is a huge time saver. Envelope publisher makes it easy to work collaboratively in large assemblies and be assured design work will fit together seamlessly.

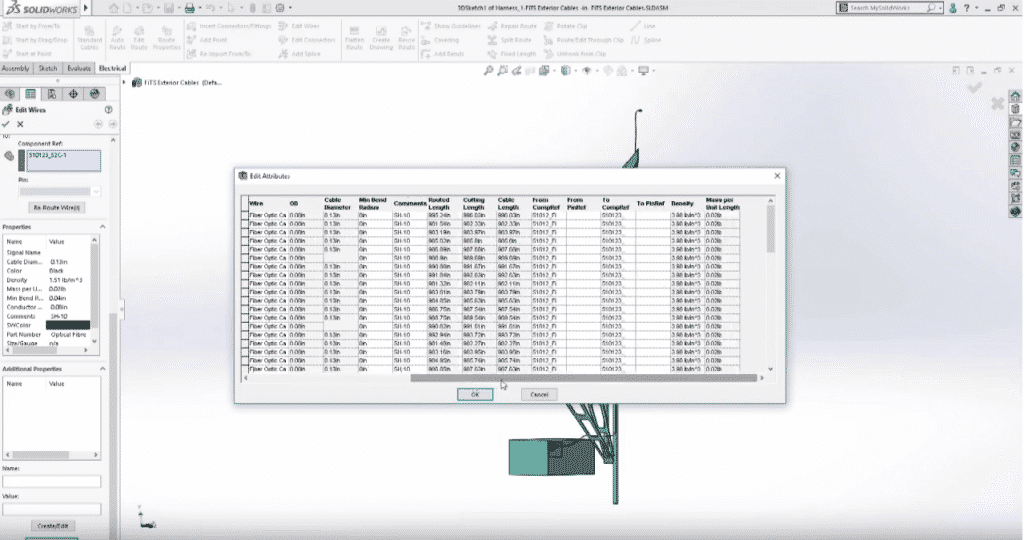

Autofill Mass Properties

Precision is extremely important. SOLIDWORKS 2020 includes the ability to fill in mass properties for wires, cables, and coverings (including partial coverings). So in addition to generating route subassemblies, with circuit summaries and connector pinout details, users will have the mass calculated automatically even as you make changes to the route. It’s calculated from the new property Mass Per Unit Length which is stored with the rest of the wire definition. SOLIDWORKS 2020 lets you easily understand how wires and cables will affect the center of mass and moment of inertia in your project.

(Image Credit: SolidWorks)

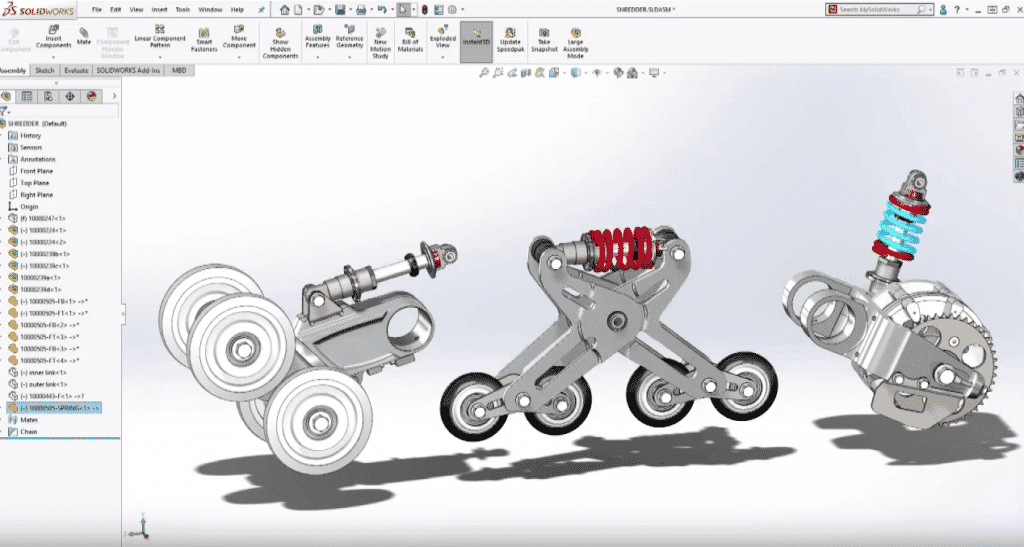

Make Flexible Parts

By now, almost everyone has experienced part features in the context of an assembly. For example in a spring, when the plates move the spring automatically adjusts – but what about cases when multiple instances of a part like this are in an assembly? In SOLIDWORKS 2020 there is a more flexible solution. Finishing the suspension upgrades, users can select the “Make Part Flexible” command here by reattaching the unique external references for each instance.

(Image Source: SolidWorks)

Does each instance need different part files or configuration? No. Do you need to make each instance virtual and redefine the external references? No. Do you need to create linked values, equations, or global variables? No. This option is so flexible you can do this with practically any part.

If you reattach external references you’ll also notice that the property manager gives you a list of all of the items to reattach. This makes it easy to get all of your necessary references to link up with the assembly. Make Part Flexible can be used for more than just springs it can be used with anything with external references that you want to make dynamic. And, the part configurations do not change, so your part drawings of these flexible parts don’t change either.

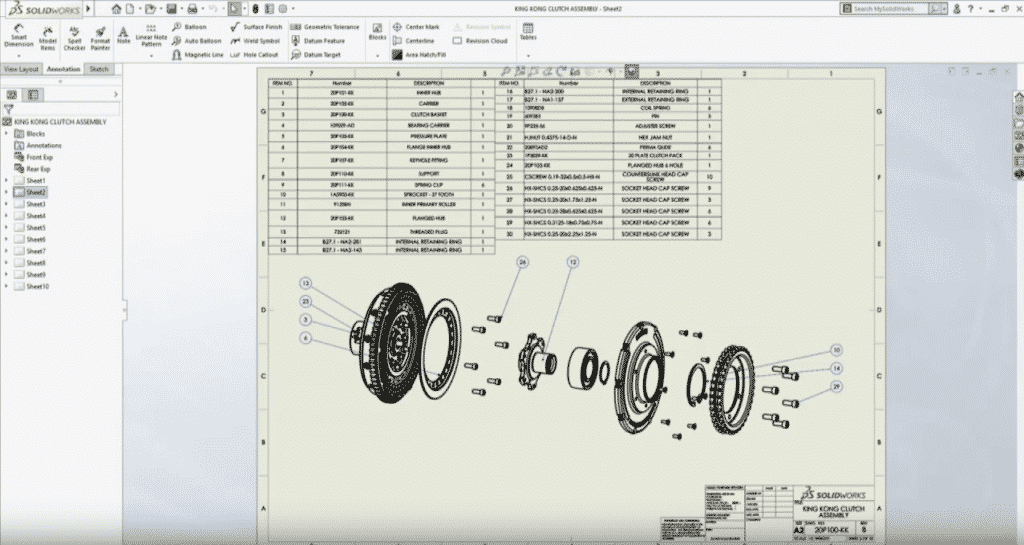

SOLIDWORKS 2020 New Detailing Mode

When opening a drawing in detailing mode in SOLIDWORKS 2020, none of the reference components are loaded so drawings, regardless of their size and complexity, can be opened in a matter of seconds. There’s no loss of detail and every drawing sheet is loaded making it perfect for reviewing your design or even just printing.

(Image Credit: SolidWorks)

What if I have to add annotations, do I need to load everything?

You do not. In detailing mode you can also annotate the drawing all of the views contain real intelligence so you can use productivity tools like auto ballooning and stay in sync with the BOMs. When a drawing is opened in detailing mode, you’re not just limited to adding annotations. You can use the design library to access all of your company standard annotations – even without any components loaded, bases and edges can still be referenced and the items remain fully editable when placed on the sheet. If needed, existing annotations can also be modified giving you complete flexibility.

When it comes to adding dimensions in detailing mode, the geometry in each view is selectable in the same way as you would in a fully resolved drawing just select the edges or vertices you need. Once placed, you can use the dimension pallet to easily add any additional information like tolerances, notes, and flags. As you work you can also take advantage of productivity shortcuts such as the format painter to replicate specific annotation styles. With a simple drag and drop, you can quickly copy and paste annotations. Finally, when you’re finished, just hit save and you’re done! Additionally, if you need to share your drawing, detailing mode allows you to save as a pdf or DWG.

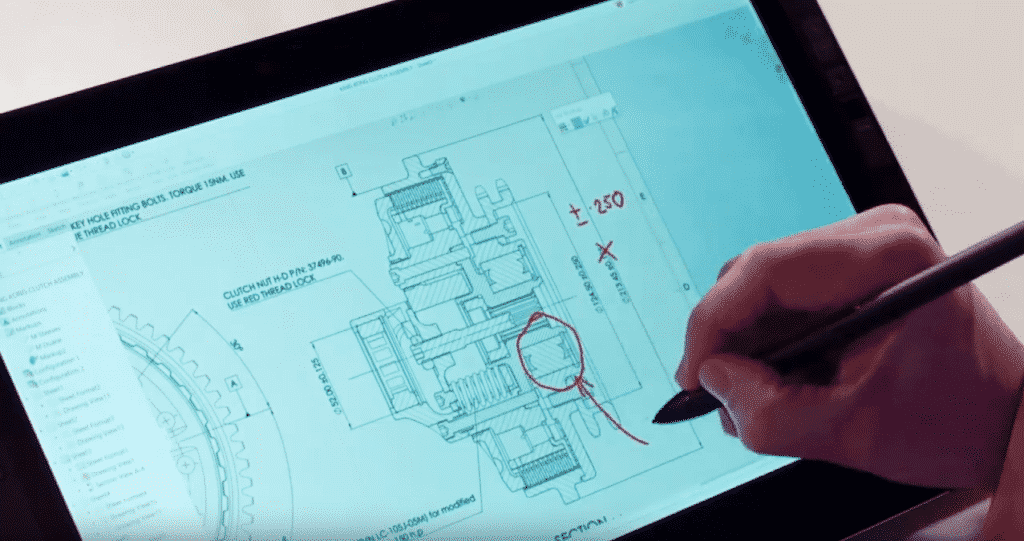

New Markup Features in SOLIDWORKS 2020

We all know good communication among design stakeholders is an essential part of a successful design process. SOLIDWORKS 2019 introduced a fantastic way to communicate design ideas by enabling you to add markups directly to parts and assemblies. A drawing is typically the main deliverable for many companies so in SOLIDWORKS 2020 you can now add markups to your drawings to create new notes and comments. Simply choose to insert to do markup view, select your preferred pen style using the color and thickness slider and you’re ready to start writing directly on the screen of your touch device. As you write, your notes are captured as well as the orientation of the markup view enabling you to easily capture and share your ideas with other members of your organization.

(Image Credit: SolidWorks)

What if I don’t have a touch-enabled device?

If you don’t have a touch-enabled device, you can still add markups just as easily by using your mouse. When you’re finished, the views are automatically stored in the markup folder where they can easily be renamed if desired to signify their purpose. Markups can then be exported in a variety of industry standard image formats or a pdf, ready to be shared with other stakeholders outside of your SOLIDWORKS design community.

Images, snapshots, and PDFs aren’t the only way you can share your markups. eDrawings 2020 lets you display markups that have been added to assemblies, parts, and drawings. All of these new enhancements to SOLIDWORKS Markups are going to make it even easier for design teams to collaborate and communicate with each other.

Are you interested in test driving SolidWorks 2020 and offering some user feedback? Click here now!

We have a vast number of openings in Northern and Southern California that are primarily looking for SolidWorks design experts. If you are interested in learning more about these roles, visit our Job Board or call us today at (408)246-5945/(714)708-3639!