Here’s a great article written by manufacturing technology writer Rob Spiegel for DesignNews.com on what’s next for 3D Printing:

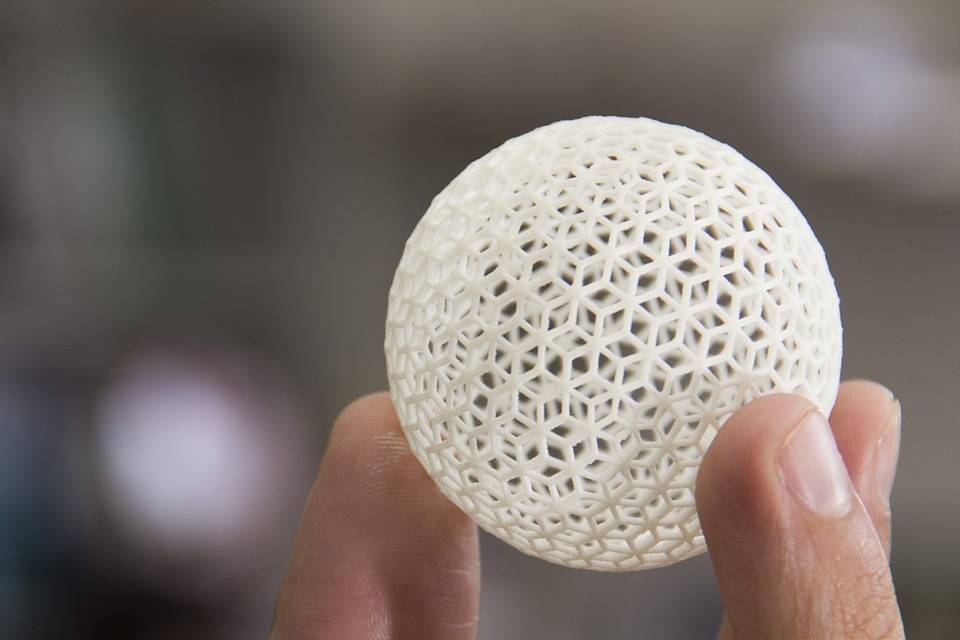

The hype is finally beginning to dissipate when it comes to the promises of 3D printing and additive manufacturing. Ok, we get it now — 3D printing can’t actually “manufacture anything.” Practicality is becoming the new path in determining production quantity and materials. At the Pacific Design and Manufacturing show earlier this month, a panel of experts in 3D printing discussed the role of materials in assessing whether an object should be printed and how it should be printed.

During the panel, The Key Differences & Benefits in Printing with Metal vs. Plastics, Cathy Lewis, consultant at CLL Management Group, noted that the application determines the material. “We need to balance our excitement about the types of material available with the needs of the specific application. If you are prototyping, stay with plastic. Then if you need a particular quality in the actual production, you can look at metal.”

Even if the production of the object needs to be metal, design iterations to get the design right may be best completed in plastic. “Design is essential. Taking your CAD knowledge and turning it into something beautiful takes time,” said Lewis. “You need design engineers who know what they’re doing, designing for performance. Play with plastic first. Then, when you do move to metal, your support structures are different, and they are more painful.”

Matching the Material to the Application

The application should determine both the material and the printing process. “We look at the application and the desired properties to help decide if laser metal is right or if something else is right,” said Melanie Lang, co-founder and managing director of Formalloy. “Metal might be required because of heat. We do a lot with aerospace and automotive, and that means some metal.”

In addition to design considerations, the life of the object in the field needs to be part of the determination on materials. “Once you get the design, then you look at materials. What is your application? Is there heat? Do we need to sterilize the part? Do you have to have a higher heat resistance to improve stiffness?” said Joe Cretella, application engineer at Protolabs. “You start to combine those properties to get to the right material.”

The quantities to be produced is another factor that needs to be taken into considerations when assessing materials. “Certain processes lend themselves to smaller parts,” said Colin Hilkene, CEO of 3Diligent. “If you are scaling up to bigger parts, you’ll need a different technology and different material.”

New Materials Are on the Way

The materials available for 3D printing are a moving target. The right material for an object may not be on the market yet. But it may be coming. “Companies continue to innovate with materials. The greatest number of new patent applications are in materials science, and much of that is for 3D printing,” said Lewis. “In the next five years, we will see an explosion of materials that have never been thought of before.”

While metal 3D printing has commanded attention during recent years, there may be non-metal materials coming that surpass the qualities of metal. “Materials is a big growth area with a steep learning curve,” said Lang. “There are a lot of new materials coming online. You can take something bronze and replace it with bronze-ish that has improved properties.”

Waiting for the 3D Printing Industry to Mature

At this point in its development, 3D printing still has plenty of growth before it reaches anything like technological maturity. As an example, post-production processing for many 3D printed objects is still a time-consuming part of the production process. “One of the biggest misconceptions about 3D printing is that you push a button and the part comes out,” said Lang. “You might have to remove it off a build plate and do machine work on it.”

Even with the promise of improved materials coming down the pike, the 3D print process itself still needs improvement. “The machines have to get faster. It’s not just the materials we’re waiting for,” said Hilkene. “The materials can work on scale to drive prices down. You also need to know about materials properties. A lot of times, 3D metal does better than casting.”

————

SoloPoint Solutions aims to keep our engineering customers updated on the latest news on design and manufacturing, including new innovations on 3D Printing. For more information about our services and how we support mechanical engineering professionals, call us today at (408)246-5945 or (714)708-3639!