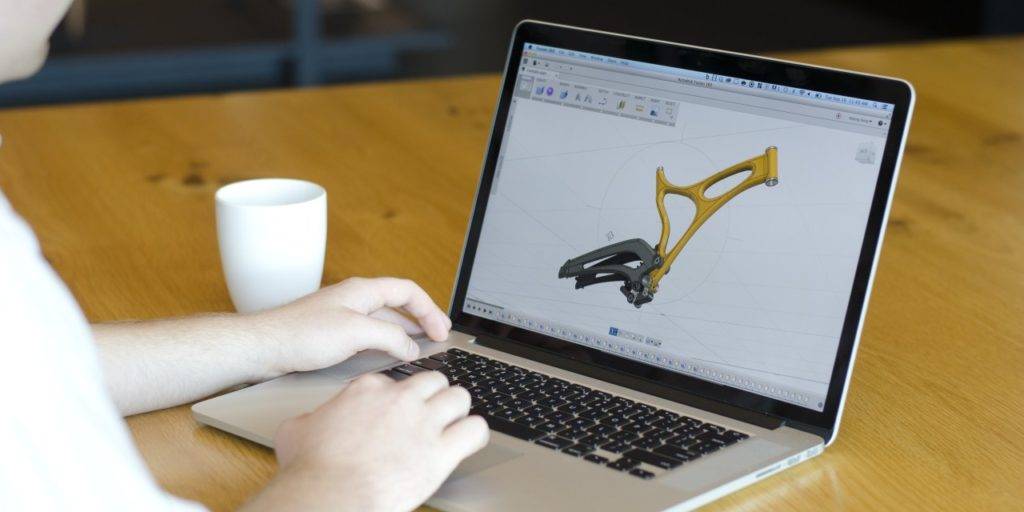

Autodesk’s answer to the cloud-based CAD system movement, Fusion 360, is seeking to be the next big thing in product development innovation. But is it worth saying goodbye to your current CAD software and switching over for? Here’s a great review of Fusion 360 by LA-based Mechanical Engineer Jonathan Landeros in engineering.com that shows its latest features and how it compares to other CAD systems in the market:

Are we tired of hearing about “paradigm shifts?” Sorry, but Fusion 360 may actually be one. There are a few situations where Fusion 360 provides real advantages over the traditional CAD systems.

There’s a Tool for That

Fusion 360 makes a comprehensive set of tools available to the user. Aside from the standard modeling tools, Fusion 360 also includes environments for creating surfaces and sheet metal parts. When it comes time for testing, there’s a simulation environment with features such as static stress and thermal analysis. The manufacturing side of things is rounded out by a robust set of aids for computer aided manufacturing (CAM).

A suite of tools for rendering—creating animations, It’s hard to find another product that has as many capabilities integrated as tightly as Fusion 360 has. All these tools are right in the program.

Render and Simulate with Infinite Computing

Some operations, by their nature, can consume a large amount of computing resources. A rendering, a thermal analysis, or a mechanical stress analysis can tie up a computer for hours as it crunches processor-intensive calculations.

Fusion 360 uses the cloud as a “resource multiplier”. Instead of tying up your design computer, processing a simulation on multiple components or generating reflections of a complicated rendering, these calculations can be sent to the cloud, where they run without taxing your system. This leaves the user the capacity to continue working on other tasks, while the calculations are running remotely.

Once complete, the user is notified that the calculations are finished, and they can review the results. If necessary, changes can be integrated, and the simulations can be run again,

That means you’re able to continue designing while calculations are running, the iteration cycle shortens. Less time for the process of iteration means more cycles happen in a shorter amount of time.

Maintaining and Updating Software Simplified

Another source of headaches with traditional CAD systems has often been the maintenance, installation and upgrading. Installing or upgrading a CAD system can be a time-consuming process because so many factors come into consideration. These could include:

- Is there any data management software on the server, and does it need to be upgraded first?

- Does the server hardware need to be upgraded?

- Do the CAD stations need to be upgraded?

- How many stations need to be installed?

- How is the system planned so users don’t encounter significant downtime?

- Which departments have to be coordinated to ensure the impact is minimized?

The items listed are really just scratching the surface. In short, installing and upgrading a traditional 3D CAD system could take hours of planning and execution.

CAD managers who have spent many an evening, weekend and holiday watching progress bars as coworkers file out of the building, wishing they could be part of that life, will appreciate this benefit.

Fusion 360 simplifies these tasks by many orders of magnitude. Since the data is stored online, there isn’t a server to worry about upgrading. When it comes to clients, the installs are of lighter weight, which translates into much less time installing.

The ripple of the reduced install time means less time having to plan for the install. Also, there’s less time to block out for an install. Since simulation and CAM are included in Fusion 360, there is a greater opportunity to unify on a single platform and ease the overall compatibility across multiple departments.

Once the initial mass installation is complete, upgrades are a simple task. Fusion updates in the background, with little interaction from the user or CAD manager. User interaction is typically limited to restarting Fusion 360 once the update is complete. Upgrading is about as seamless as it can possibly be.

The Downsides

With all of the upsides I’ve described in Fusion 360, you might think there are no downsides and Fusion 360 is full of unicorns and rainbows. But, no tool is perfect. There are some items that need to be addressed when looking at Fusion 360.

Fusion 360 is still a relatively new CAD program. It may not have all the tools that we’ve become accustomed to in traditional CAD tools. That may mean you have to use workarounds more often than you would like. While Fusion 360 is continually being improved and developed, patience can be a virtue when it comes down to waiting for some features to evolve into the software.

While Fusion 360 has the ability to create versions of files, there isn’t a way of creating true revisions. It’s up to the user to document and update when a drawing is released at a given revision level. Release control and tracking, via engineering change request and change orders, don’t exist in Fusion 360 at this point, so users who need this may be out in the cold.

As secure as Fusion 360 is, some companies simply will not embrace a cloud-based solution. It may be part of the culture, or regulatory or security requirements.

Bottom Line

Fusion 360 is a great design tool that should be considered if you’re looking for a primary design software or as a supplementary program to an existing design tool. The vast collection of tools and ease of sharing data can go a long way to streamlining the design process.

As many positives as Fusion 360 has, nothing is perfect. There are still features to be developed. Some companies may not be able to adopt it without robust workflows for revision control. The cloud-based portion, one of Fusion 360’s key features, may scare off potential users obsessed with security, despite the proven safety of cloud software in general.

After taking all considerations into account, I must say Fusion 360 would be a key addition to most every CAD user’s toolbox.renderings and drawings—rounds out the toolbox, ensuring that nearly every aspect of design is covered.

To try Fusion 360 for free, go to the Autodesk website right now: www.autodesk.com/products/fusion-360/free-trial

For engineers who are proficient with Autodesk products or other CAD systems, SoloPoint Solutions has a wide array of job openings for you! Check out our Job Board today!