At the Design 2 Part (D2P) Show held at the Santa Clara Convention Center on May 20-21, SoloPoint was fortunate enough to have the opportunity to chat with local manufacturing service providers and see the latest advancement in Rapid Prototyping.

There were several companies that showcased their Rapid Prototyping capabilities at the D2P Show and what stood out about each of these companies are the different materials being used in making prototypes

Proto Technologies, located on Booth# 411, had a sprawl of their latest prototype samples that were mostly made by their Fused Deposition Modeling (FDM) Machines using materials such as nylons and thermoplastics; but one of the items that stood out from their exhibit was a clear circular part made by their Stereolithography (SLA) machine. This is an example of their capabilities of printing using RenShape SL 7870, a clear resin that makes the finished part look clear like glass. This material is ideal for mechanical engineers who require a clear surface to view the part’s intricate interior details and test for its functionality.

Another company exhibiting their latest products is 3D Systems. They were showcasing their QuickPart Solutions line which includes their Direct Metal Printing (DMP) services. With DMP, engineers can submit their CAD designs that require materials such as titanium, aluminum or stainless steel. This technology is a possible alternative to traditional machining in producing tooling inserts or for creating highly detailed metal prototypes.

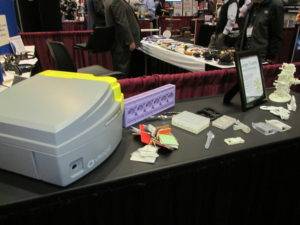

Plastic prototypes were still the most commonly seen products at the show. Protogenic: A Tenere Company, had a whole spread of plastic prototypes ranging in different sizes from small parts that are the size of a hand to bigger parts such as their sample of a virus counter for one of their biotech clients. One portion of their display that was eye-catching was the prototypes made by their Laser Sintering machines. These samples were made in DuraForm GM Plastics, glass filled nylons, which are ideal for parts that need to have extra rigidity and are heat resistant. With this material, mechanical engineers will able to test their prototypes for temperature resistance and durability.

Learning about the latest Rapid Prototyping processes and materials allows the team at SoloPoint Solutions to know first-hand what innovation could impact how engineers develop products. This knowledge helps us in understanding how to provide staffing services for companies embracing these innovations.

Need help hiring for your mechanical design team? Call the experts at SoloPoint Solutions today at (866)626-3322.